Table of Contents

Every year, countless hardware startups burn through millions in funding, and established companies abandon promising products—not because the technology doesn’t work, but because they failed to navigate the complexities of hardware development. The harsh reality is that the “move fast and break things” mentality that works in software becomes a death sentence in hardware, where each broken iteration can cost thousands of dollars and weeks of delay.

At Croxel, we’ve guided dozens of IoT products from initial concept through successful market launch by applying a proven, structured methodology that transforms the chaotic process of hardware development into a predictable, manageable journey. This framework, refined through years of real-world experience developing everything from medical wearables to industrial monitoring systems, provides the roadmap that separates successful products from expensive failures.

Why Hardware Development Demands Discipline

The fundamental difference between hardware and software development comes down to physics, economics, and time. While software engineers can experiment freely in virtual environments, hardware engineers must contend with the immutable laws of physics, the brutal economics of manufacturing, and the extended timelines of physical prototyping.

The 1-10-100 Rule: Why Early Decisions Matter

The most critical concept in hardware development is understanding how the cost of changes increases exponentially as development progresses:

- Design Phase: Making a change costs $1

- Validation Phase: The same change costs $10

- Production Phase: That change now costs $100

This exponential cost growth creates a fundamental imperative: get it right early, because getting it wrong late is catastrophically expensive. Unlike software, where you can refactor aggressively and deploy fixes instantly, hardware changes require new prototypes, retesting, recertification, and potentially new tooling—each step adding weeks or months to your timeline.

Risk Compounding Through Development

In hardware development, risks don’t just add up—they multiply. A component selection decision made in the concept phase affects power consumption, which influences battery selection, which impacts mechanical design, which determines manufacturing costs, which affects market positioning. Each design decision creates ripple effects throughout the system.

The answer isn’t to avoid risk—it’s to manage risk systematically through progressive validation. By organizing development into distinct phases with clear objectives and exit criteria, teams can address different types of risks at the appropriate time, when they’re least expensive to resolve.

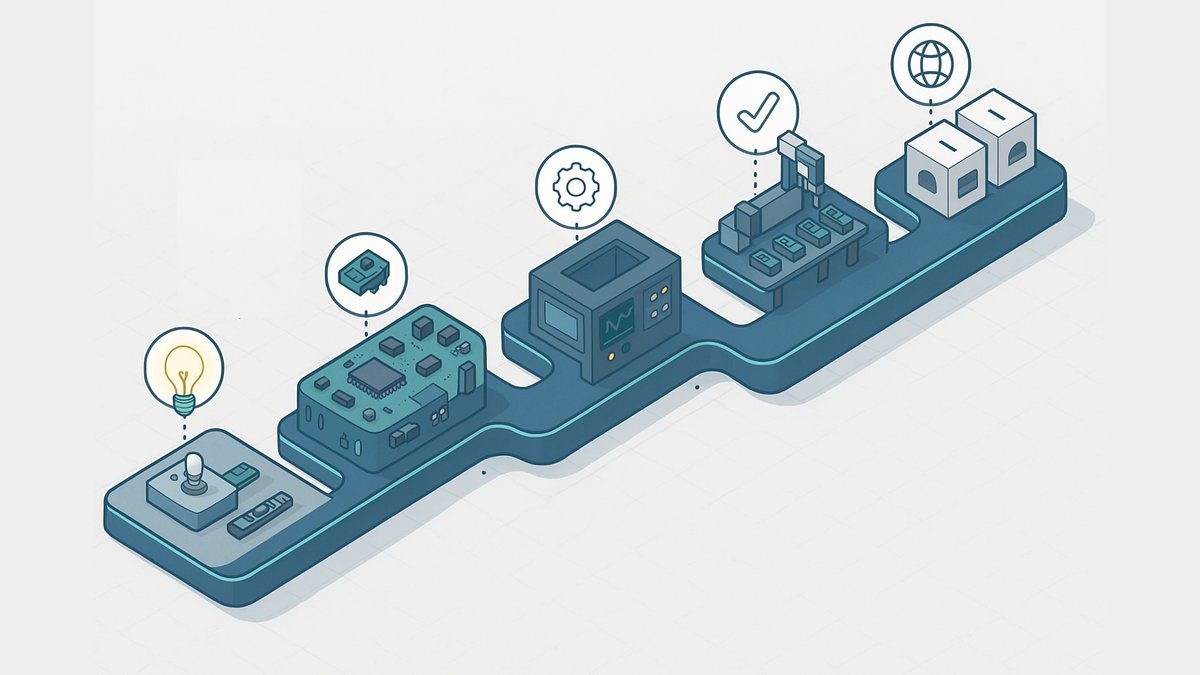

The 5-Phase Development Framework

Our development methodology balances speed with thoroughness, enabling teams to move quickly through early phases while building confidence for larger investments in later stages. Each phase has distinct objectives, activities, deliverables, and success criteria that must be met before proceeding.

Phase 1: POC - Prove the Concept (Weeks 1-8)

Objective: Validate technical feasibility and core assumptions before committing to full development.

The Proof of Concept phase bridges the gap between theoretical planning and practical implementation. This isn’t about building a miniature version of the final product—it’s about answering fundamental questions:

- Will the core technology work?

- Can we achieve the required performance?

- What are the biggest technical risks?

Key Activities:

- Prototype with development kits and evaluation boards

- Test critical technologies in isolation

- Validate power consumption estimates

- Confirm wireless connectivity performance

- Identify major technical risks

Power-First Philosophy: One critical differentiator in our POC approach is systematic power analysis. While many teams leave power optimization for later phases, we’ve learned that power consumption fundamentally drives architecture decisions. Early power profiling helps teams understand the real constraints they’re working within and make informed trade-offs between performance and battery life.

Success Criteria:

- Core functionality demonstrated

- Critical technologies validated

- Major risks identified with mitigation strategies

- Architecture proven feasible

- Go/no-go decision supported by data

Typical Investment: $10K-50K

Phase 2: EVT - Build It Right (Weeks 9-20)

Objective: Implement complete functionality in the target form factor with production-intent performance.

Engineering Validation Testing transforms proof-of-concept demonstrations into engineering reality. This phase marks the transition from “it can work” to “it does work”—implementing all required features in custom hardware that approaches the final product’s characteristics.

Key Activities:

- Design custom PCBs with production components

- Develop firmware architecture and core functionality

- Create mechanical prototypes

- Integrate all subsystems

- Validate component selections

Modern Firmware Foundation: EVT is where firmware transitions from experimental code to production architecture. Our approach leverages modern real-time operating systems like Zephyr, which provide robust foundations for complex IoT applications. This architectural investment pays dividends throughout the product lifecycle, enabling faster feature development, easier debugging, and more reliable operation.

Success Criteria:

- All features function correctly on custom hardware

- Performance meets requirements

- Form factor achievable

- Component availability confirmed

- Design ready for optimization

Typical Investment: $50K-150K

Phase 3: DVT - Make It Production-Ready (Weeks 21-32)

Objective: Optimize the design for manufacturing, compliance, and market requirements while validating reliability.

Design Validation Testing transforms engineering prototypes into production-ready designs. This phase focuses on the critical transition from “it works in the lab” to “it works reliably at scale.”

Key Activities:

- Optimize for manufacturing (DFM reviews)

- Environmental and reliability testing

- Regulatory compliance preparation

- Beta testing with real users

- Supply chain validation

Manufacturing Partnership Approach: Rather than treating manufacturing as an afterthought, we integrate manufacturing considerations from the earliest design phases. This includes:

- Early engagement with contract manufacturers

- Joint design reviews with production engineers

- Systematic evaluation of assembly processes

- Component standardization for availability

Regulatory Integration: DVT includes preparation for regulatory testing and certification. Teams that consider regulatory requirements during architecture and component selection phases generally navigate certification smoothly, while those who treat compliance as a DVT activity often face design changes and schedule delays.

Success Criteria:

- Design meets all requirements consistently

- Manufacturing processes defined and validated

- Regulatory approvals obtained or in progress

- User testing confirms positive experience

- Ready for pilot production

Typical Investment: $150K-300K

Phase 4: PVT - Validate at Scale (Weeks 33-40)

Objective: Validate production processes, optimize yields, and ensure consistent quality at volume.

Production Validation Testing focuses on the manufacturing process rather than the product design. This phase validates that products can be built consistently at scale with acceptable yields, quality levels, and costs.

Key Activities:

- Pilot production runs (100-1000 units)

- Yield optimization

- Test procedure validation

- Quality system implementation

- Supply chain stress testing

Test Development Excellence: Our approach to production testing goes beyond basic functional verification to include comprehensive validation of all critical parameters. We develop automated test systems that can efficiently verify product performance while providing detailed data for yield analysis and process optimization.

Success Criteria:

- Production yields meet targets (>95%)

- Quality systems detect and prevent defects

- Supply chain demonstrates readiness

- Cost targets achieved

- Ready for volume production

Typical Investment: $200K-500K

Phase 5: MP - Deliver and Support (Ongoing)

Objective: Scale manufacturing while maintaining quality and supporting the product throughout its market lifecycle.

Mass Production represents the culmination of the development journey, where focus shifts from development to delivery and lifecycle management.

Key Activities:

- Production scaling

- Quality monitoring

- Field performance tracking

- Firmware updates and improvements

- Cost reduction initiatives

Lifecycle Partnership Model: Our approach extends beyond initial production support to include:

- Ongoing firmware enhancements

- Field issue resolution

- Manufacturing optimization

- Next-generation planning

Success Metrics:

- Consistent quality at volume

- Field failure rates below targets

- Customer satisfaction maintained

- Cost improvements realized

- Platform ready for evolution

Making the Framework Work for You

Adapting to Your Context

While this framework provides a proven structure, successful implementation requires adaptation to your specific context:

For Startups: Focus on rapid POC validation to prove market viability before significant investment. Consider modular approaches that allow incremental funding aligned with phase gates.

For Established Companies: Leverage existing infrastructure and supplier relationships while ensuring new product development doesn’t compromise current operations. Phase gates become critical for resource allocation decisions.

For Regulated Industries: Integrate compliance requirements from POC forward. Regulatory considerations should influence every phase rather than being addressed separately.

Critical Success Factors

Clear Requirements: Success begins with well-defined, stable requirements. Changes become exponentially more expensive as development progresses.

Phase Gate Discipline: Resist the temptation to skip phases or proceed without meeting exit criteria. The framework only works when phases build on solid foundations.

Manufacturing Integration: Involve manufacturing partners early. Design decisions made without manufacturing input often require expensive changes later.

Power and Connectivity Focus: For IoT products, power consumption and wireless reliability determine market success. These cannot be afterthoughts.

Your Next Steps

The path from concept to successful product launch is challenging but entirely achievable with the right approach. This framework provides the structure, but success requires:

- Honest Assessment: Evaluate your current capabilities against the requirements of each phase

- Strategic Planning: Develop realistic timelines and budgets based on the framework

- Team Building: Ensure access to necessary expertise, whether internal or through partners

- Commitment to Process: Resist shortcuts that compromise long-term success

Ready to transform your hardware development approach? The framework is proven—the question is whether you’re ready to implement it with the discipline required for success.

Whether you’re starting a new product development journey or looking to improve your current process, understanding and applying this 5-phase framework can mean the difference between joining the ranks of successful hardware products or becoming another cautionary tale of what could have been.

Related Topics

About the Author

Albert Garvett

CEO & Co-Founder

Electrical Engineer with 25+ years of experience in business management and product development. Leads Croxel's strategic vision and product development initiatives, applying results-oriented methodologies to guide high-performance engineering teams. Expert in transforming complex IoT concepts into market-ready solutions across diverse industries.

Albert Garvett has written 3 articles for Croxel Insights.